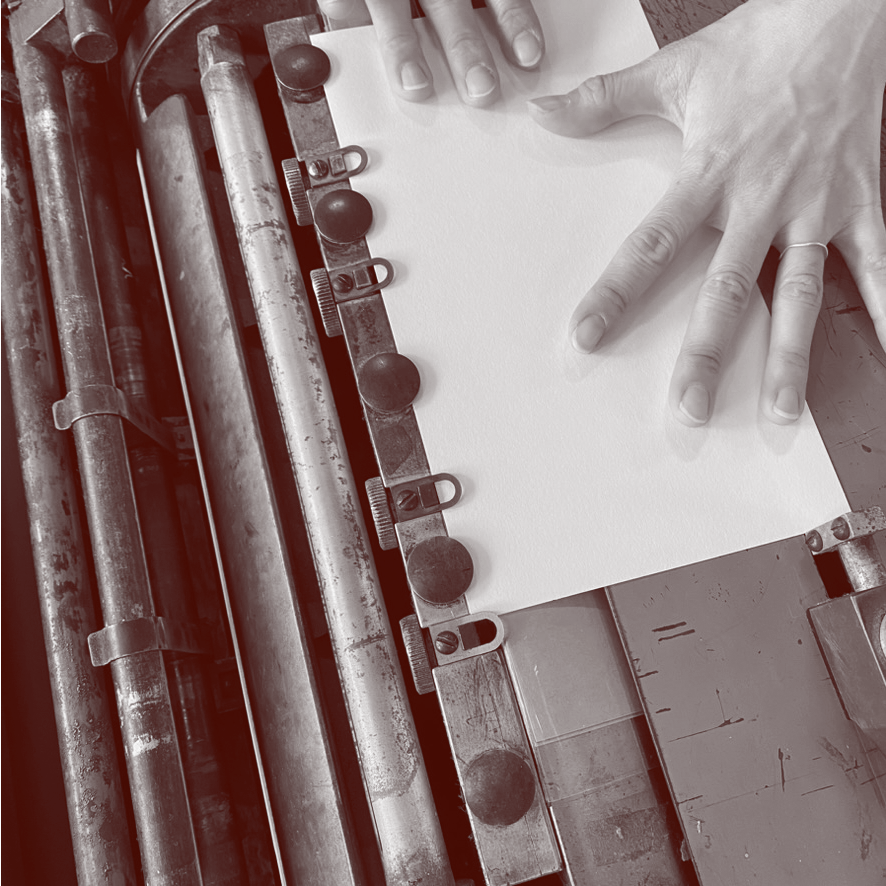

PRESS RENTALS

AVAILABLE TUESDAYS - THURSDAYS FROM 10AM-4PM

You can now book time at The Aesthetic Union and use our presses to bring your designs to life! To qualify, you must complete a Press Training Workshop.

Press rental starts at $30 per hour, which includes ink and full access to one of our presses. An expert printer will be on-site to assist you and answer any questions you may have.

Email us at info@theaestheticunion.com to reserve your spot. Be sure to give us at least two days' notice before your desired time. Our press is available during our weekday business hours.

BEFORE YOUR PRESS RENTAL

-

GET PRESS RENTAL CERTIFIED

Attend a workshop to get certified before you can rent the press.

-

PREPARE YOUR DIGITAL FILE

Make sure your file meets our specific file guidelines.

-

SUBMIT YOUR FILE FOR PLATEMAKING

Send in your final file for platemaking prior to your rental.

-

CHOOSE YOUR PAPER

Visit the shop to select paper from our sample books. Note: Please order paper at least one week in advance of your rental. We can’t place paper orders until your invoice has been paid.

-

BOOK YOUR RENTAL TIME

Email us at info@theaestheticunion.com to reserve your spot. Be sure to give us at least two days' notice before your desired time. Our press is available during our weekday business hours.

Step-by-step press operation

shop rules

-

INK KNIVES

You need one ink knife per color. Avoid cross-contaminating ink colors.

-

Weighing Ink

Never put in right on the scale, always use a peice of paper as your palette. Just don't forget to tare before adding ink!

-

CLEANING THE PRESS

Do not use hand towels or blue shop rags to clean the press. Only use the gray rags located in the basket on the ink-mixing cart. To dispose of a dirty rag, place it in the red or gray bin under the other Vandercook (219).

setting up the press

STEP ONE

CHECK THE PACKING

Packing controls the impression depth. Ensure the paper's edge is flush where the packing meets the plate. There should be no ghost image on the paper, and the paper should sit flush with the guides and grippers.

STEP TWO

SET UP THE PLATE

Take a sheet of paper and align it with the deadline (the thin line between the motor roller and the base, which shows where the grippers will land). Stick the plate to the base, ensuring it’s centered relative to your paper. Use the grid to align with your crop marks.

STEP THREE

CHECK THE REGISTRATION

Run a sheet of paper through the press with no ink. Use a pica stick to make sure the crop marks are evenly spaced from the paper’s leading edge.

STEP FOUR

FINALIZE SETUP

Once everything is aligned and you're happy with the impression, you’re ready to ink up!

Inking the press

STEP ONE

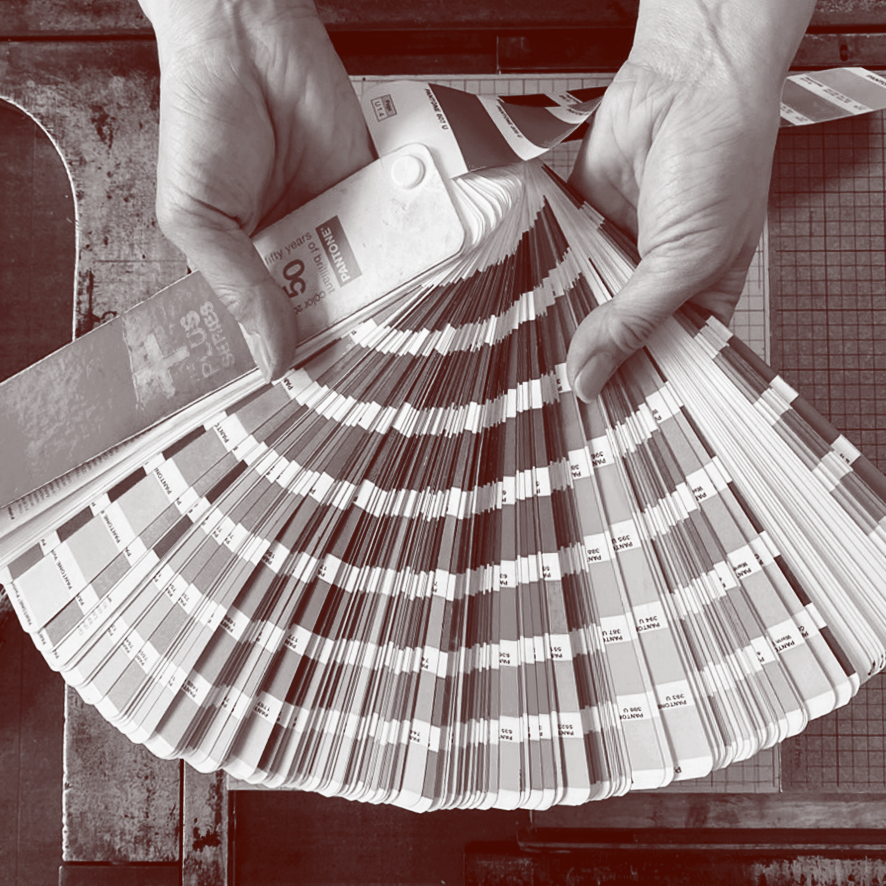

CHOOSE YOUR INK COLOR

Pick a color from our Pantone book. Keep in mind that the inks we use are translucent, so the color of the paper will affect the final result.

STEP TWO

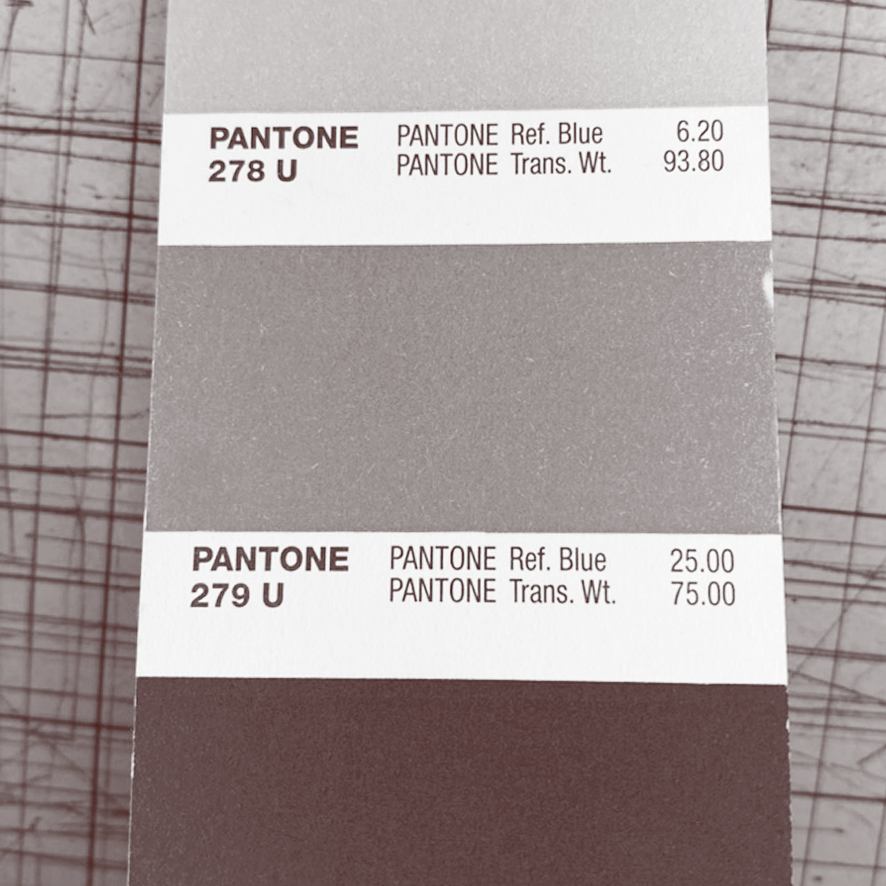

MIX THE INK

The color recipe is listed below each Pantone swatch. The numbers next to each color add up to 100. For mixing, we use grams, so divide each value by 10 for your ratio. For example, Rubine Red 78.9 becomes 7.89 grams, which rounds to 7.9 grams for our scale.

STEP THREE

WEIGH THE INK

Zero out the scale with a piece of paper on it. Use the palette knife to scoop ink and weight out on the scale according to the new ratios. Be sure not to cross-contaminate the colors, and use only one palette knife per color.

STEP FOUR

MIX THE INK

Once you have the correct amount of each color, scrape the ink onto the glass mixing panel and begin mixing until uniform.

STEP FIVE

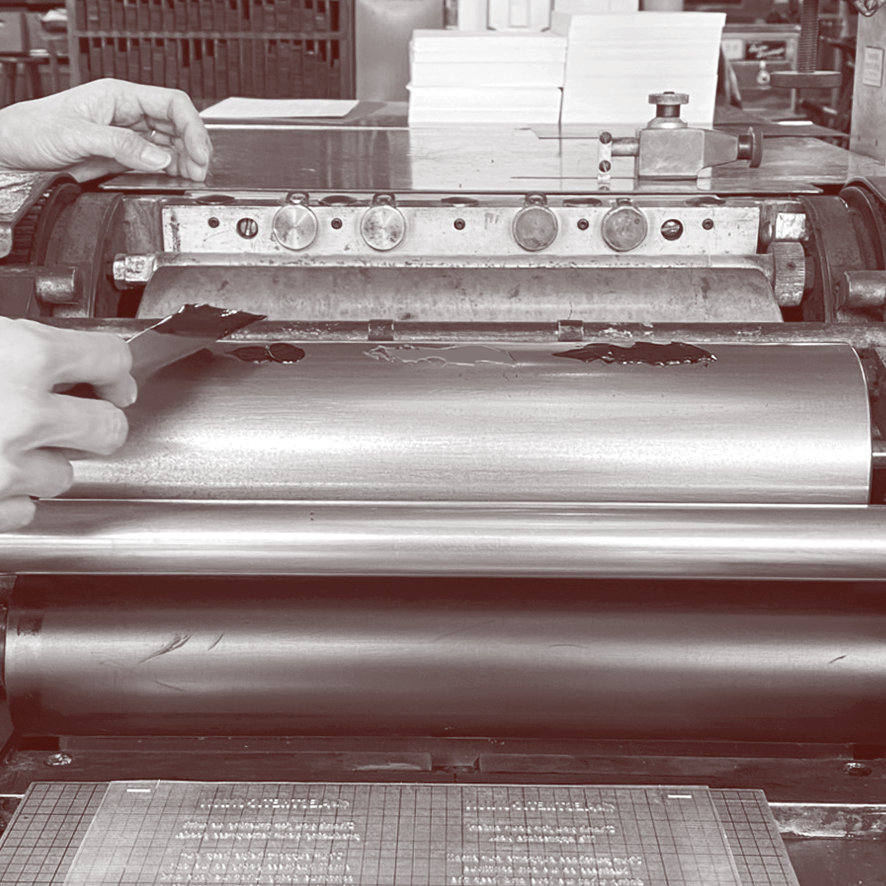

APPLY THE INK

When the ink is fully mixed, apply it to the oscillating roller. Be sure the roller is either lifted or not spinning before you ink. Use your palette knife to spread the ink evenly across the roller. We recommend starting lighter and adding more ink as need. If you find that you’ve applied to much ink, adjust the ink density.

STEP SIX

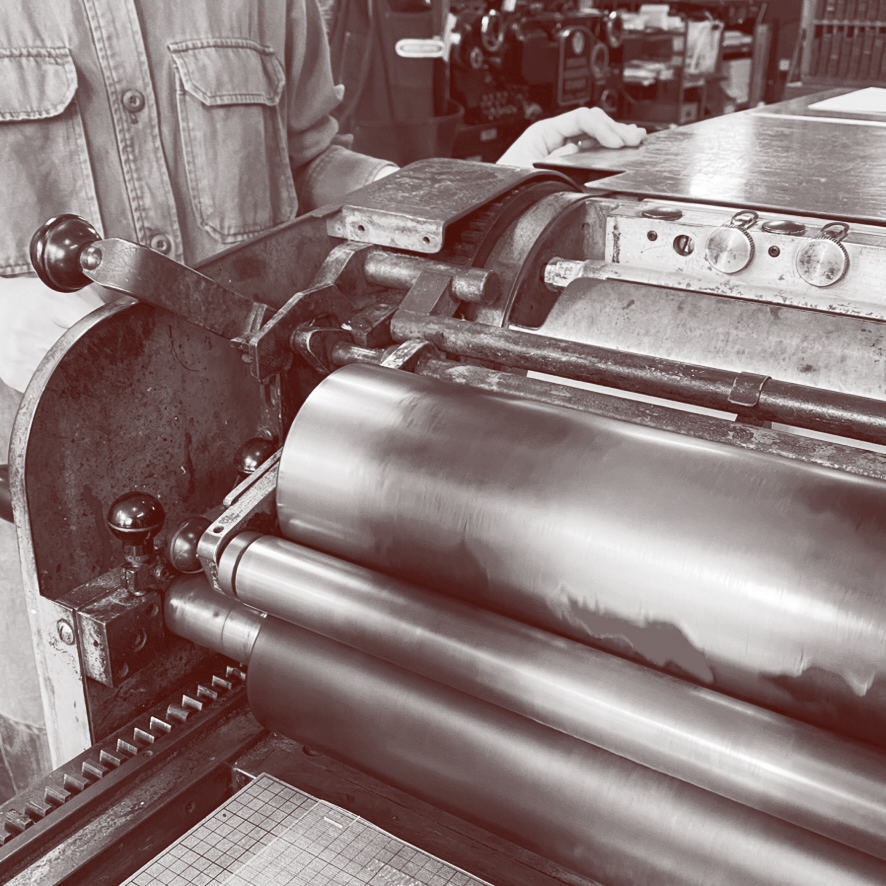

MILL THE INK

Set the rollers down and turn on the press to mill the ink. Once the ink is uniform across the roller, you’re ready to print!

STEP SEVEN

ADJUST INK DENSITY

If the ink is too heavy, roll the cylinder forward and clean the motor roller with a rag and alcohol. Do a test print and repeat until you achieve your desired ink density.

finally, you can start printing

LOAD THE PAPER

With everything set up, press the foot pedal and insert the paper into the guides and under the grippers. Release the pedal and start cranking! There should be slight resistance when you crank. If it's too difficult, remove some packing from the cylinder.

MAINTAIN REGISTRATION

To keep registration as even as possible, make sure the top guide is secure and insert the paper evenly and flush into the grippers.

cleaning the press

CLEANING FLUIDS

We have three pump bottles for cleaning:

- Liquid Genie (brown fluid)

- Water (clear with yellow spout)

- 99% Isopropyl Alcohol (clear fluid with plain spout)

These bottles are designed to be squeezed, not tilted. Always hold them upright and squeeze the body to spray from the nozzle.

CLEAN THE PRESS ROLLERS

Start by folding a press rag into a small square (about 3x3 inches). As you clean, refold the rag so the clean side is up.

ORDER OF CLEANING

1. Liquid Genie: apply directly to oscillating roller

2. Water: apply directly to oscillating roller

3. Isopropyl Alcohol: apply to rag, wipe down press

Thank you for respecting our workspace, tools and equipment during your press rental!